Nickel has a marked effect on the colour of Cu-Ni alloys. The copper colour becomes lighter as nickel is added. Alloys are almost silvery white from about 15% nickel. The lustre and purity of the colour increases with nickel content; from about 40% nickel, a polished surface can hardly be distinguished from that of silver.

The density of copper (8.93 kg/dm3at 20 °C) varies only slightly with increasing nickel content (density of nickel at 20 °C = 8.9 kg/dm3) and is 8.9 kg/dm3 for all Cu-Ni alloys specified in DIN 17 664.

The high thermal conductivity of pure copper of 394 W/(m.K) is severely reduced by nickel; it reaches a minimum of c. 21 W/(m.K) at about 45% Ni. The coefficient of linear expansion initially decreases sharply with addition of nickel, then more slowly. The specific heat (at 20 °C) of copper is 0.385 J/(g.K) and of nickel is 0.452 J/(g. K). As nickel content increases, it first diminishes slightly and a mean value of 0.377 J/(g.K) can be expected.

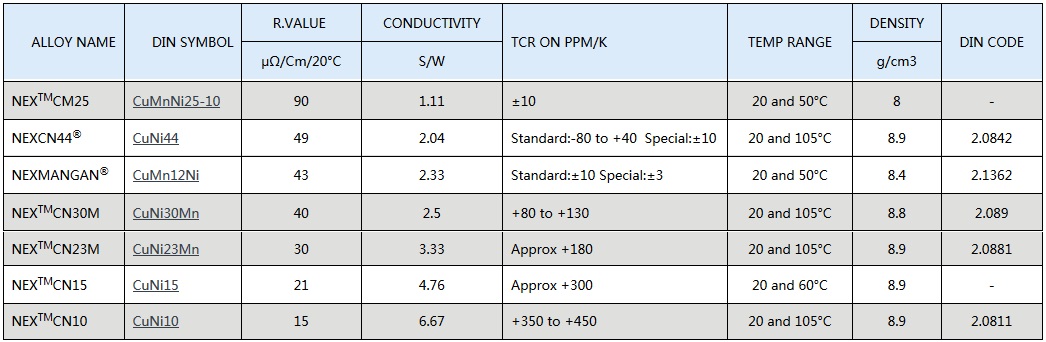

The electrical resistivity of Cu-Ni resistance alloys at different temperatures rises steeply with nickel content, so that Cu-Ni alloys are suitable as resistance materials. A maximum occurs at c. 45% Ni. The minimum of the temperature coefficient of electric resistance is in approximately the same concentration range.

The high thermoelectric power of Cu-Ni alloys in the range between 40 and 50% Ni is particularly noteworthy compared with other metals such as iron, copper, platinum etc. They are therefore especially suitable for use in thermocouples for temperature measurements in a moderate temperature range. The high thermoelectric force of CuNi44 excludes its use as resistance material in low-voltage appliances, because the copper connections to CuNi44 form a thermocouple.

Cu-Ni alloys do not exhibit any ferromagnetism. Copper is diamagnetic, nickel is ferromagnetic. Nickel-copper alloys change from diamagnetic via paramagnetic to ferromagnetic as nickel content increases. Depending on the alloy, iron has a small effect when it is present in solid solution. If iron is precipitated, these ferromagnetic microscopic particles lead to a macroscopic increase of ferromagnetism.

The precipitate-free matrix remains diamagnetic or paramagnetic. Cu-Ni alloys containing 20 to 25% Ni and 20% Fe or about 25% Co are pronounced magnetic materials. As a result of their high remanence and coercive force, they are also suitable for permanent magnets.

Attend exhibitions, focus on industry devolpment trend and new technology,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achieving continuous development.

TAG: Copper Nickel Alloy